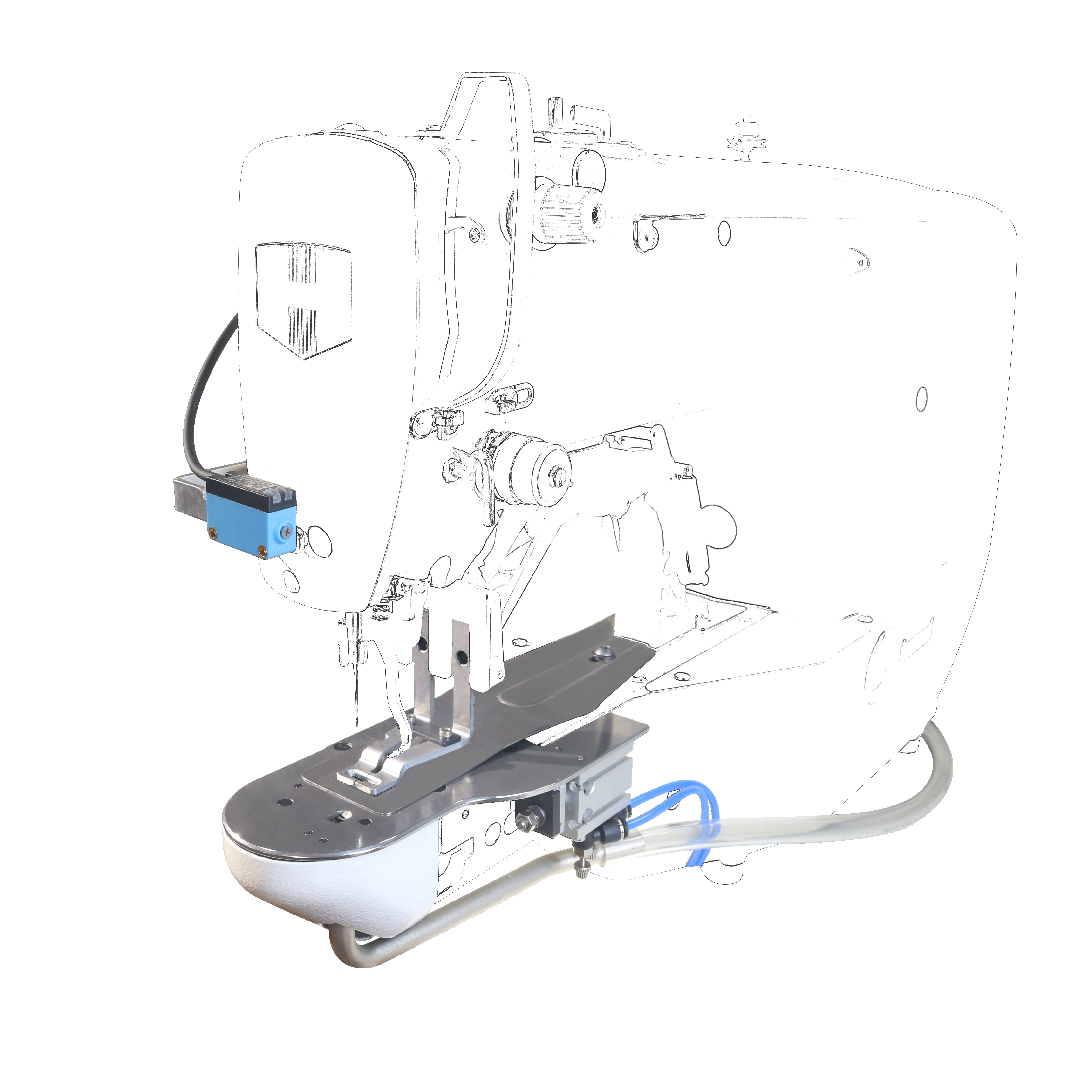

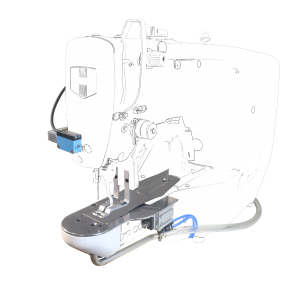

JUKI 1900A Auto Thread Trimmer & Cutter Devices Installed In Bar Tacking Industrial Sewing Machines

Bar tacking machine series automatic thread trimmer device:

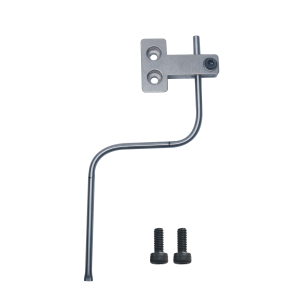

After finishing the 4-needle 6-thread stitching process for knitted fabric garments, socks, etc., there will be a section of thread, which needs to be manually cut off, and then a bar tacking machine is used to reinforce the beginning of the fabric patchwork. Dawnsing auto thread trimmer & cutter manufacture has designed a series of automatic thread trimmers for bar tacking machines. A movable knife and a fixed knife are installed under the needle plate for automatic thread trimming, which reduces the manual link. After the 4-needle and 6-thread seam is finished, the next process is that the thread ends on the fabric are automatically cut off on the bar tacking machine, and there is no problem of off-thread, and the bar tack is neat, beautiful and consistent. Both the Brother 430 Tackle and the Heavy Duty 1900 Tackle fit. According to the different models of different brands of electronic control, Dawnsing can provide three ways of storage card, chip and electronic file transmission for the bar tack specification (pattern) in the original system of the bar tacking machine.

Bar tacking machine automatically drives the thread trimmer, first cuts the thread ends and thread ends on the cloth, and collects the cut thread ends and thread ends in a centralized manner. The thread trimming device has a simplified operation mode, easy assembly and automatic thread trimming function. feature. And timely drive the air blowing, thread trimming and suction to blow the suture head on the cloth piece into the guide channel and cut it and suck it up to the suction, and use the first detection unit to detect whether the sewer pulls the suture tail to the The guide channel is used to drive the thread trimming unit and the suction unit to cut the thread tail and pump the thread to the suction unit, so as to achieve the efficiency of automatic operation. A base is arranged on the side edge of the sewing platform of the sewing machine, and a thread trimming unit and a positioning seat are arranged on the base. connected, and a first detection unit is installed on both sides of the guide channel, and a second detection unit is installed at the sewing machine body corresponding to the sewing platform, and the sewing machine body corresponding to the guide channel A blowing unit is installed According to this, use the second detection unit to detect the position of the cloth piece, and drive the air blowing unit, the thread trimming unit and the suction unit in time, so as to blow the sewing thread head on the cloth piece into the guide channel and cut it and suck it to the suction In addition, the first detection unit is used to detect whether the stitcher pulls the thread tail to the guide channel, so as to drive the thread cutting unit and the suction unit to cut the thread and suck the thread tail to the suction unit, so as to achieve automation performance of work.

-300x300.png)

-300x300.png)